Global Custom Manufacturer, Integrator, Consolidator, Outsourcing Partner for a Wide Variety of Products & Services.

We are your one-stop source for manufacturing, fabrication, engineering, consolidation, integration, outsourcing of custom manufactured and off-shelf products & services. We also private label / white label your products with your brand name if you wish.

Choose your Language

-

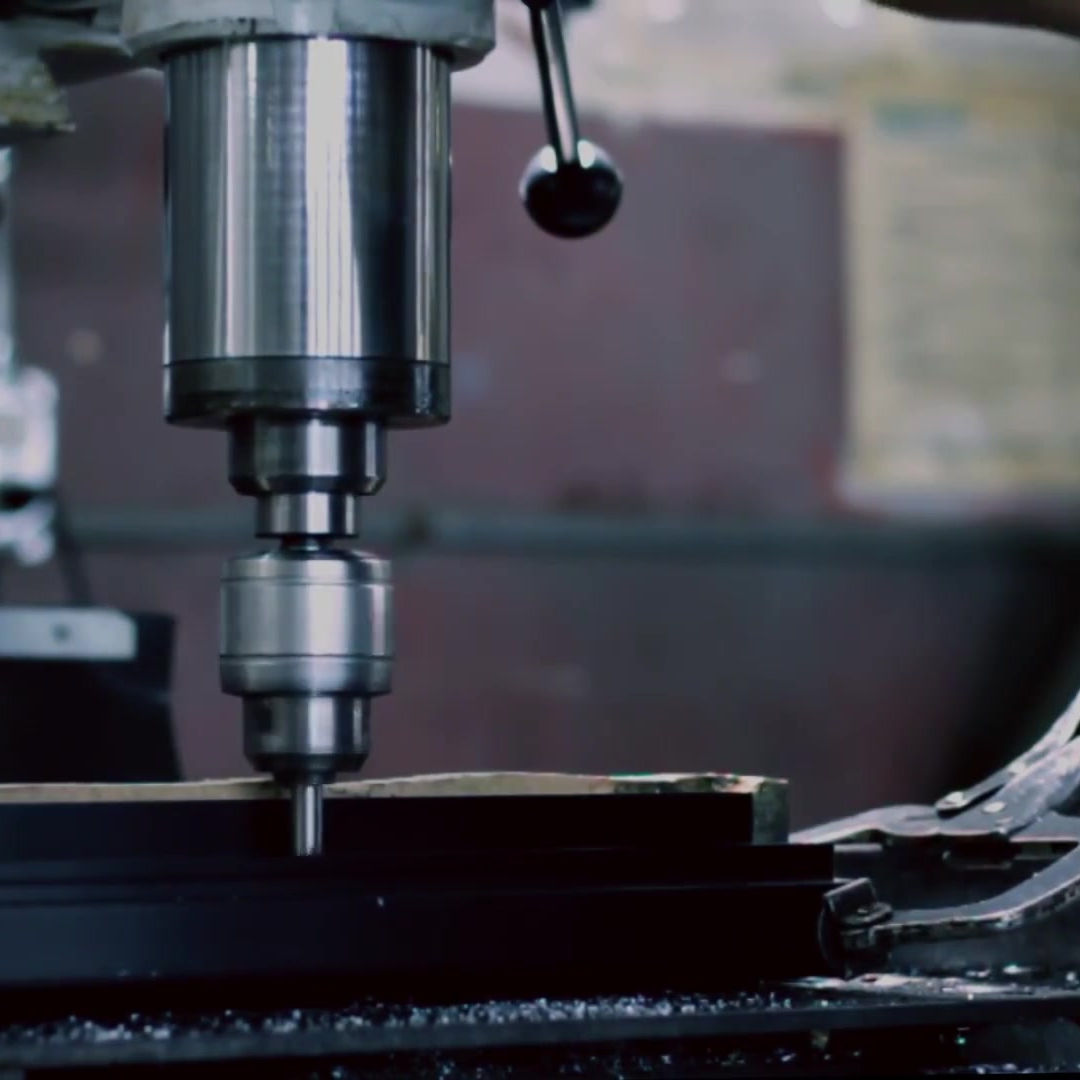

Custom Manufacturing of Parts, Components, Assemblies, Finished Products, Machines and Industrial Equipment

-

Domestic & Global Contract Manufacturing

-

Manufacturing Outsourcing

-

Domestic, Global Procurement of Industrial Products

-

Private labeling / White Labeling your Products with your Brand Name

-

Product Finding & Locating Services

-

Global Design and Channel Partnership

-

Engineering Integration

-

Engineering Services

-

Global Consolidation, Warehousing, Logistics

Filters & Filtration Products & Membranes

We supply filters, filtration products and membranes for industrial and consumer applications. Products include:

- Activated carbon based filters

- Planar wire mesh filters made to customer's specifications

- Irregular shaped wire mesh filters made to customer's specifications.

- Other type of filters such as air, oil, fuel filters.

- Ceramic foam and ceramic membrane filters for various industrial applications in petrochemistry, chemical manufacturing, pharmaceuticals...etc.

- High performance clean room and HEPA filters.

We stock off-the-shelf wholesale filters, filtration products and membranes with various dimensions and specifications. We also manufacture and supply filters & membranes according to customers specifications. Our filter products comply with international standards such as CE, UL and ROHS standards. Please click on the links below to select the filtration product of your interest.

Activated Carbon Filters

Activated carbon also called activated charcoal, is a form of carbon processed to have small, low-volume pores that increase the surface area available for adsorption or chemical reactions. Due to its high degree of microporosity, just one gram of activated carbon has a surface area in excess of 1,300 m2 (14,000 sq ft). An activation level sufficient for useful application of activated carbon may be attained solely from high surface area; however, further chemical treatment often enhances adsorption properties.

Activated carbon is widely used in filters for gas purification, filters for decaffeination, metal extraction & purification, filtration & purification of water, medicine, treatment of sewage, air filters in gas masks and respirators, compressed air filters, filtering of alcoholic beverages like vodka and whiskey from organic impurities which can affect taste, odor and color among many other applications. Activated carbon is being used in various types of filters, most commonly in panel filters, non-woven fabric, cartridge type filters....etc. You can download brochures of our activated carbon filters from the links below.

- Air Purification Filters (includes folded type and V-shaped Activated Carbon Air Filters)

Ceramic Membrane Filters

Ceramic membrane filters are inorganic, hydrophilic, and are ideal for extreme nano-, ultra-, and micro-filtration applications that require longevity, superior pressure/temperature tolerances and resistance to aggressive solvents. Ceramic membrane filters are basically ultra-filtration or micro-filtration filters, used to treat wastewater and water at higher elevated temperatures. Ceramic membrane filters are produced from inorganic materials such as aluminum oxide, silicon carbide, titanium oxide, and zirconium oxide. The membrane porous core material is first formed through extrusion process which becomes the support structure for the ceramic membrane. Then coatings are applied to the inner face or the filtering face with the same ceramic particles or sometimes different particles, depending on the application. For example, if your core material is aluminum oxide, we also use aluminum oxide particles as the coating. The size of ceramic particles used for the coating, as well as the number of coating applied will determine the pore size of the membrane as well as the distribution characteristics. After depositing the coating to the core, high-temperature sintering takes place inside a furnace, making the membrane layer integral of the core support structure. This provides us a very durable and hard surface. This sintered bonding ensures a very long life for the membrane. We can custom manufacture ceramic membrane filters for you from micro-filtration range to ultra-filtration range by varying the number of coatings and by using the right particle size for the coating. Standard pore sizes can vary from 0.4 microns to .01 micron size. Ceramic membrane filters are like glass, very hard and durable, unlike polymeric membranes. Therefore ceramic membrane filters offer a very high mechanical strength. Ceramic membrane filters are chemically inert, and they can be used at a very high flux compared to polymeric membranes. Ceramic membrane filters can be vigorously cleaned and are thermally stable. Ceramic membrane filters have a very long operational life, roughly three to four times as long compared to the polymeric membranes. Compared to polymeric filters, ceramic filters are very expensive, because ceramic filtration applications start where the polymeric applications end. Ceramic membrane filters have various applications, mostly in treating very difficult to treat water and wastewater, or where high temperature operations are involved. It also has vast applications in oil and gas, wastewater recycling, as a pre‑treatment for RO, and for removing precipitated metals from any precipitation process, for oil & water separation, food and beverage industry, microfiltration of milk, clarification of fruit juice, reclamation and collection of nano powders and catalyzers, in the pharmaceutical industry, in mining where you have to treat the wasted tailing ponds. We offer single channel as well as multiple channel shaped ceramic membrane filters. Both off-the-shelf as well as custom manufacturing is offered to you by AGS-TECH Inc.

Ceramic Foam Filters

Ceramic foam filter is a tough foam made from ceramics. Open-cell polymer foams are internally impregnated with ceramic slurry and then fired in a kiln, leaving only ceramic material. The foams may consist of several ceramic materials such as aluminium oxide, a common high-temperature ceramic. Ceramic foam filters get insulating properties from the many tiny air-filled voids within the material. Ceramic foam filters are used for filtration of molten metal alloys, absorption of environmental pollutants, and as substrate for catalysts requiring large internal surface area. Ceramic foam filters are hardened ceramics with pockets of air or other gases trapped in pores throughout the body of the material. These materials can be fabricated as high as 94 to 96% air by volume with high temperature resistances such as 1700 °C. Since most ceramics are already oxides or other inert compounds, there is no danger of oxidation or reduction of the material in ceramic foam filters.

- Ceramic Foam Filters Brochure

- Ceramic Foam Filter User's Guide

HEPA Filters

HEPA is a type of air filter and the abbreviation stands for High-Efficiency Particulate Arrestance (HEPA). Filters meeting the HEPA standard have many applications in clean rooms, medical facilities, automobiles, aircraft and homes. HEPA filters must satisfy certain standards of efficiency such as those set by the United States Department of Energy (DOE). To qualify as HEPA by US government standards, an air filter must remove from the air that passes through 99.97% of particles that are sized 0.3 µm. HEPA filter's minimal resistance to airflow, or pressure drop, is generally specified as 300 pascals (0.044 psi) at its nominal flow rate. HEPA filtration works by mechanical means and does not resemble the Ionic and Ozone filtration methods which use negative ions and ozone gas respectively. Therefore, the chances of potential pulmonary side-effects like asthma and allergies is much lower with HEPA filtering systems. HEPA filters are also used in high quality vacuum cleaners effectively to protect users from asthma and allergies, because HEPA filter traps fine particles such as pollens and dust mite feces which trigger allergy and asthma symptoms. Contact us if you would like to get our opinion about using HEPA filters for a particular application or project. You can download our product brochures for off-the-shelf HEPA filters below. If you cannot find the right size or shape you would need we will be happy to design and manufacture custom HEPA filters for your special application.

- Air Purification Filters (includes HEPA Filters)

- Private Label Industrial Filters (We can put your company name and logo on these filters. Includes also HEPA filters)

Coarse Filters & Pre-Filtering Media

Coarse filters and pre-filtering media are used to block large debris. They are of critical importance because they are inexpensive and protect the more expensive higher grade filters from being contaminated with coarse particulates and contaminants. Without coarse filters and pre-filtering media, the cost of filtering would have been much much higher as we would need to change fine filters much more frequently. Most of our coarse filters and pre-filtering media are made of synthetic fibers with controlled diameters and pore sizes. Coarse filter materials include the popular material polyester. Filtering efficiency grade is an important parameter to check for before choosing a particular coarse filter / pre-filtering media. Other parameters and features to check for are whether the pre-filtering media is washable, reusable, arrestance value, resistance against air or fluid flow, rated air flow, dust and particulate holding capacity, temperature resistance, flammability, pressure drop characteristics, dimensional and shape related specification...etc. Contact us for opinion before choosing the right coarse filters & pre-filtering media for your products and systems.

- Wire Mesh and Cloth Brochure (includes information on our wire mesh & cloth filters manufacturing capabilities. Metal and nonmetal wire cloth can be used as coarse filters and pre-filtering media in some applications)

- Air Purification Filters (includes Coarse Filters & Pre-Filtering Media for air)

Oil, Fuel, Gas, Air and Water Filters

AGS-TECH Inc. designs and manufactures oil, fuel, gas, air and water filters according to customer's requirements for industrial machinery, automobiles, motorboats, motorcycles...etc. Oil filters are designed to remove contaminants from engine oil, transmission oil, lubricating oil, hydraulic oil. Oil filters are used in many different types of hydraulic machinery. Oil production, transportation industry, and recycling facilities also employ oil and fuel filters in their manufacturing processes. OEM orders are welcome, we label, silkscreen print, laser mark oil, fuel, gas, air and water filters according to your requirements, we put your logos on the product and package according to your needs and requirements. If desired, housing materials for your oil, fuel, gas, air, water filters can be customized depending on your particular application. Information about our standard off-the-shelf oil, fuel, gas, air and water filters can be downloaded below.

- Private Label Industrial Filters (We can put your company name and logo on these filters)

Membranes

A membrane is a selective barrier; it allows some things to pass through but stops others. Such things may be molecules, ions, or other small particles. Generally, polymeric membranes are used to separate, concentrate, or fractionate a wide variety of liquids. Membranes serve as a thin barrier between miscible fluids that allow for preferential transport of one or more feed components when a driving force is applied, such as a pressure differential. We offer a suite of nanofiltration, ultrafiltration and microfiltration membranes that are engineered to provide optimal flux and rejection and can be customized to meet the unique requirements of specific process applications. Membrane filtration systems are the heart of many separation processes. Technology selection, equipment design, and fabrication quality are all critical factors in the ultimate success of a project. To start, the proper membrane configuration must be selected. Contact us for help in your projects.