Global Custom Manufacturer, Integrator, Consolidator, Outsourcing Partner for a Wide Variety of Products & Services.

We are your one-stop source for manufacturing, fabrication, engineering, consolidation, integration, outsourcing of custom manufactured and off-shelf products & services. We also private label / white label your products with your brand name if you wish.

Choose your Language

-

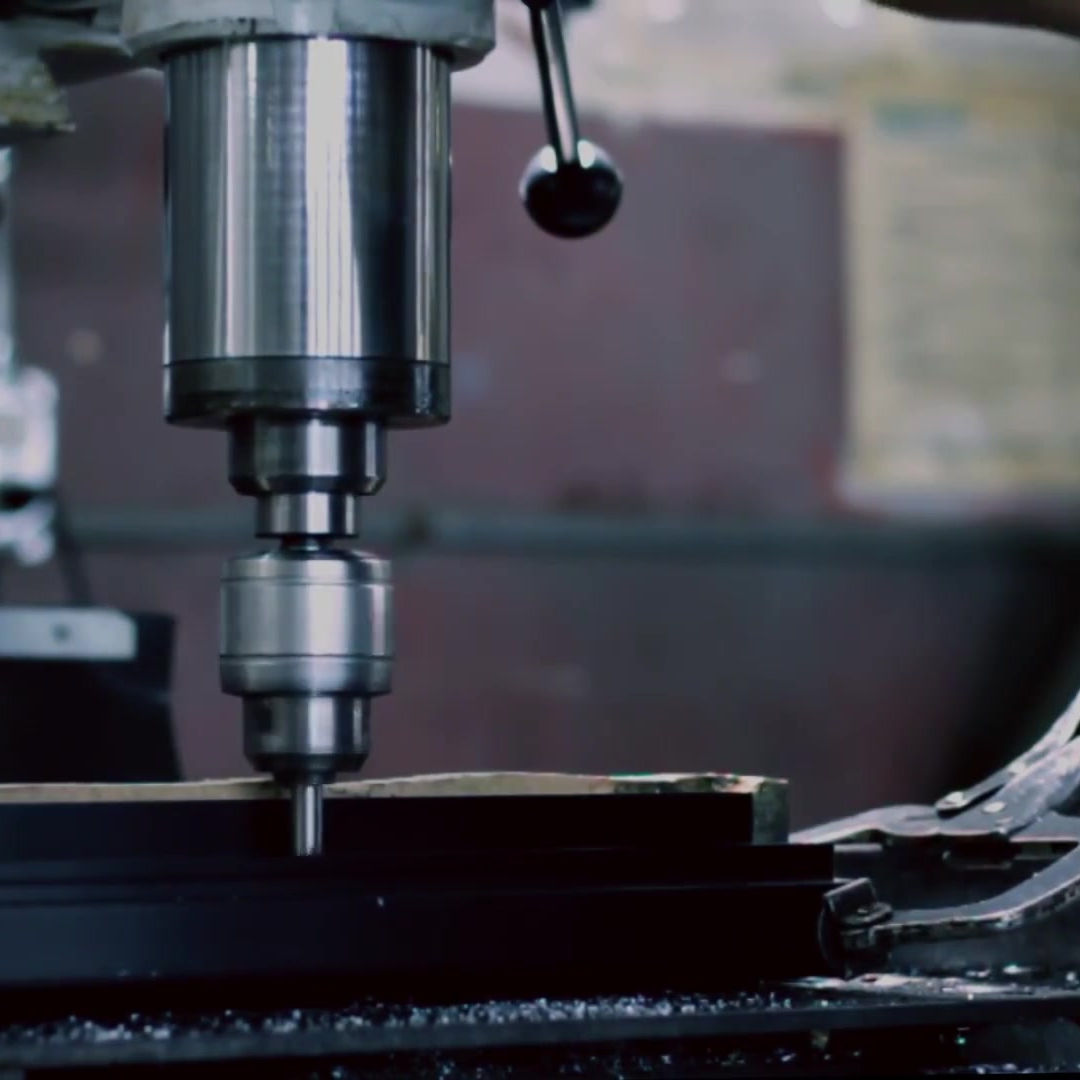

Custom Manufacturing of Parts, Components, Assemblies, Finished Products, Machines and Industrial Equipment

-

Domestic & Global Contract Manufacturing

-

Manufacturing Outsourcing

-

Domestic, Global Procurement of Industrial Products

-

Private labeling / White Labeling your Products with your Brand Name

-

Product Finding & Locating Services

-

Global Design and Channel Partnership

-

Engineering Integration

-

Engineering Services

-

Global Consolidation, Warehousing, Logistics

A MECHANICAL SEAL is a device which helps join systems or mechanisms together by preventing leakage, containing pressure, or excluding contamination. Mechanical seals can vary in their construction from a simple-O-Ring to complicated assembled structures containing lubricants inside labyrinth shaped canals and self-aligning functionality. Many types of mechanical seals are available. Some of our mechanical seals are available from stock and can be ordered by catalog part number, and on the other hand custom manufacturing option of mechanical seals is available for our customers. So we can design and manufacture mechanical seals specially for your application. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.

Major MECHANICAL SEAL TYPES we offer are: Induction sealing or cap sealing, Adhesive sealant, Bridgman seal, a piston sealing mechanism that creates a high pressure reservoir from a lower pressure source, Bung, Coating, Compression seal fitting, Diaphragm seal, Ferrofluidic seal, Gasket or Mechanical Packing, Flange gasket, O-ring, V-ring, U-cup, Wedge, Bellows, D-ring, Delta rings, T-rings, Lobed ring, O-ring boss seal, Piston ring, Glass-ceramic-to-metal seals, Hose coupling, various types of hose couplings, Hermetic seal, Hydrostatic seal, Hydrodynamic seal, Labyrinth seal, a seal which creates a tortuous path for the liquid to flow through, Lid (container), Rotating face mechanical seal, Face seal, Plug, Radial shaft seal, Trap (siphon trap), Stuffing Box, Gland Assembly (mechanical packing), Split Mechanical Seal, Wiper seal, Dry gas seal, Exitex seal, Radial seal, Felt radial seal, Radial positive-contact seals, Clearance seals, Split-ring seal, Axial mechanical seal, End face seals, Molded packings, Lip-type and squeeze type packing, Static seals and sealants, Flat nonmetallic gaskets, Metallic gaskets, Exclusion seals (wiper, scraper, axial and boot seals)

Our stocked mechanical seals include famous brands including Timken, AGS-TECH as well as other quality brands. Below you can click and download catalogues of some of the most popular seals. Please tell us the catalogue number/model number and the quantity you would like to order and we will offer you the best prices and lead times along with offers for alternative brands similar in quality. We can supply original brand name as well as generic brand name mechanical seals.

TIMKEN SEALS:

- Download Timken Large Bore Industrial Seal Catalog

Small Bore Bonded Seal Catalog

NSC Manufacturers

NSC Numeric & Metric

NSC Numerical Lists

NSC Oil Seals 410027- 9Y9895

NSC O Rings Oil Seals up to 410005

NSC Size Section

MATERIALS USED IN MECHANICAL SEALS: All our mechanical seals are assembled from the finest materials. The type of lubricant and the mean operating temperature generally govern the choice of elastomer to be used for the mechanical seal compound. Nitrile rubber compounds are among the most widely used sealing materials because temperatures seldom exceed 220 F (105 C). Nitrile rubber has good wear characteristics, easy to mold and inexpensive sealing materials used in seals. For some seals special oil resistant silicone compounds are preferred. For high end applications fluoroelastomer compounds such as Viton are used in seals because they have a long life at very high temperatures in almost any lubricant. Seals incorporating fluoroelastomers are higher in cost however. At low temperatures fluoroelastomers get stiff but not brittle.