Global Custom Manufacturer, Integrator, Consolidator, Outsourcing Partner for a Wide Variety of Products & Services.

We are your one-stop source for manufacturing, fabrication, engineering, consolidation, integration, outsourcing of custom manufactured and off-shelf products & services. We also private label / white label your products with your brand name if you wish.

Choose your Language

-

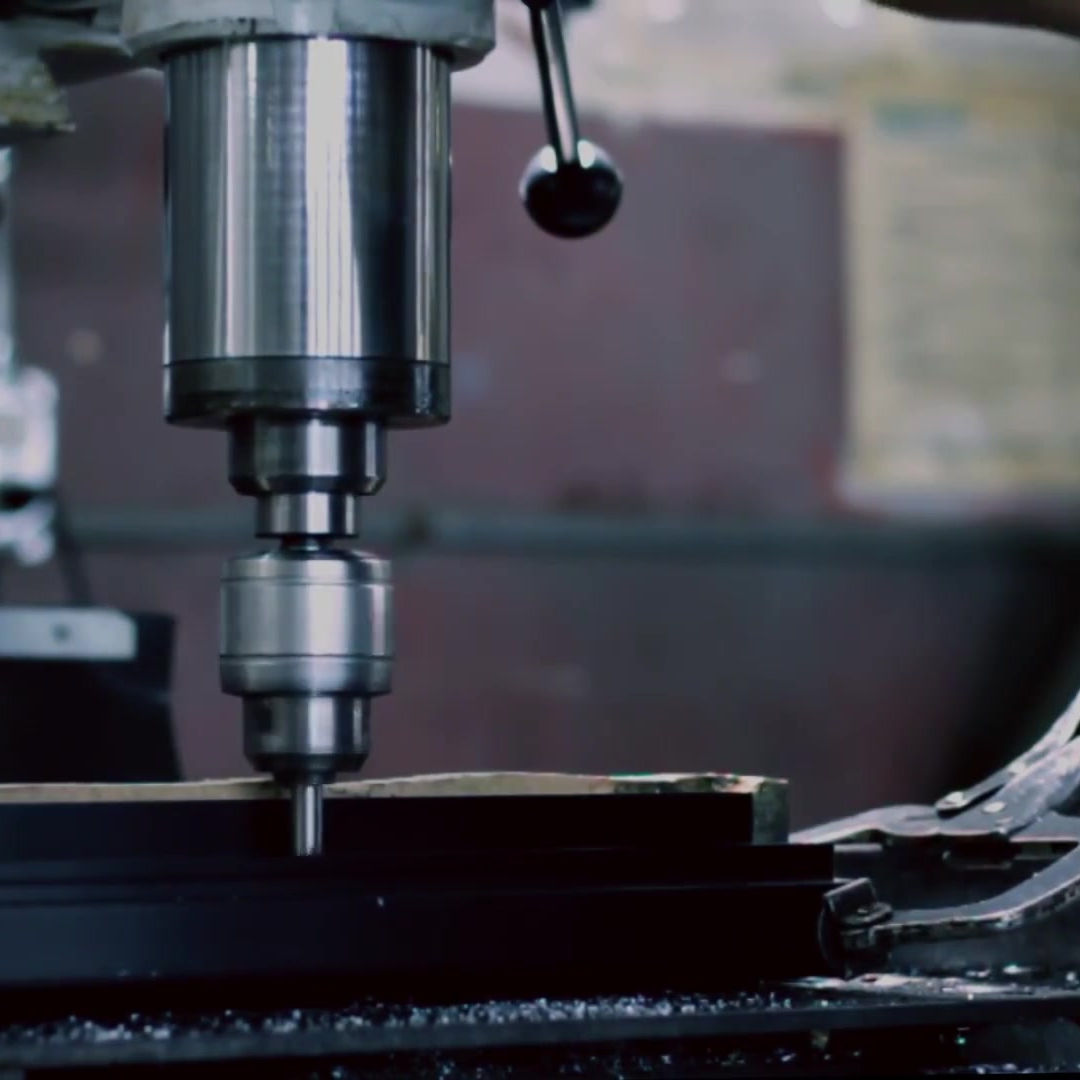

Custom Manufacturing of Parts, Components, Assemblies, Finished Products, Machines and Industrial Equipment

-

Domestic & Global Contract Manufacturing

-

Manufacturing Outsourcing

-

Domestic, Global Procurement of Industrial Products

-

Private labeling / White Labeling your Products with your Brand Name

-

Product Finding & Locating Services

-

Global Design and Channel Partnership

-

Engineering Integration

-

Engineering Services

-

Global Consolidation, Warehousing, Logistics

A drive shaft, driveshaft, driving shaft, propeller shaft (prop shaft), or Cardan shaft is defined as a mechanical component for transmitting rotation and torque, generally deployed to connect other components of a drive train that cannot be connected directly because of distance or the need to allow for relative movement between them. Generally speaking, there are mainly two types of shafts: Transmission shafts are used to transmit power between the source and the machine absorbing power; e.g. counter shafts and line shafts. On the other hand, machine shafts are the integral part of the machine itself; e.g. crankshaft.

To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, rag joints, a splined joint or a prismatic joint.

We sell shafts for transportation industry, industrial machinery, work equipment. According to your application, the proper material is chosen with appropriate weight and strength. While some applications require lightweight shafts for lower inertia, others necessitate very strong materials to stand the extremely high torques and weight. Call us today to discuss your application.

We use a variety of techniques to assemble shafts with their mating parts. According to the environment and application, here are a few of our techniques for engaging shafts and their mating parts:

SPLINED SHAFT: These shafts have multiple grooves, or key-seats cut around its circumference for a portion of its length in order that a sliding engagement may be made with corresponding internal grooves of a mating part.

TAPERED SHAFT: These shafts have a tapered end for easy and strong engagement with the mating part.

Shafts may also be connected to their mating parts by other means such as setscrews, press fit, sliding fit, slip fit with key, pins, knurled joint, driven key, brazed joint…etc.

SHAFT & BEARING & PULLEY ASSEMBLY: This is another area where we have the expertise to manufacture reliable assemblies of bearings and pulleys with shafts.

SEALED SHAFTS: We seal shafts and shaft assemblies for grease and oil lubrication and protection from dirty environments.

MATERIALS USED FOR MANUFACTURING SHAFTS: The materials we use for ordinary shafts is mild steel. When high strength is required, an alloy steel such as nickel, nickel-chromium or chromium-vanadium steel is used.

We form shafts generally by hot rolling and finish them to size by cold drawing or turning and grinding.

OUR STANDARD SHAFT SIZES:

Machine shafts

Up to 25 mm steps of 0.5 mm

Between 25 to 50 mm steps of 1 mm

Between 50 to 100 mm steps of 2 mm

Between 100 to 200 mm steps of 5 mm

Transmission shafts

Between 25 mm to 60 mm with 5 mm steps

Between 60 mm to 110 mm with 10 mm steps

Between 110 mm to 140 mm with 15 mm steps

Between 140 mm to 500 mm with 20 mm steps

The standard lengths of the shafts are 5 m, 6 m and 7 m.

Please click on highlighted text below to download our relevant catalogs and brochures on off-shelf shafts:

- Round and square shafts for linear bearings & linear shafting