Global Custom Manufacturer, Integrator, Consolidator, Outsourcing Partner for a Wide Variety of Products & Services.

We are your one-stop source for manufacturing, fabrication, engineering, consolidation, integration, outsourcing of custom manufactured and off-shelf products & services. We also private label / white label your products with your brand name if you wish.

Choose your Language

-

Custom Manufacturing of Parts, Components, Assemblies, Finished Products, Machines and Industrial Equipment

-

Domestic & Global Contract Manufacturing

-

Manufacturing Outsourcing

-

Domestic, Global Procurement of Industrial Products

-

Private labeling / White Labeling your Products with your Brand Name

-

Product Finding & Locating Services

-

Global Design and Channel Partnership

-

Engineering Integration

-

Engineering Services

-

Global Consolidation, Warehousing, Logistics

We manufacture custom wires, wire assembly, wires formed into desired 2D and 3D shapes, wire nets, mesh, enclosures, basket, fence, wire spring, flat spring; torsion, compression, tension, flat springs and more. Our processes are wire and spring forming, wire drawing, shaping, bending, welding, brazing, soldering, piercing, swaging, drilling, chamfering, grinding, threading, coating, fourslide, slide forming, winding, coiling, upsetting. We recommend that you click here to

DOWNLOAD our Schematic Illustrations of Wire and Spring Forming Processes by AGS-TECH Inc. This downloadable file with photos and sketches will help you better understand the information we are providing you below.

• WIRE DRAWING : Using tensile forces we stretch the metal stock and draw it through a die to reduce the diameter and increase its length. Sometimes we use a series of dies. We are capable of making dies for every gauge of wire. Using material of high tensile strength we draw very thin wires. We offer both cold and hot worked wires.

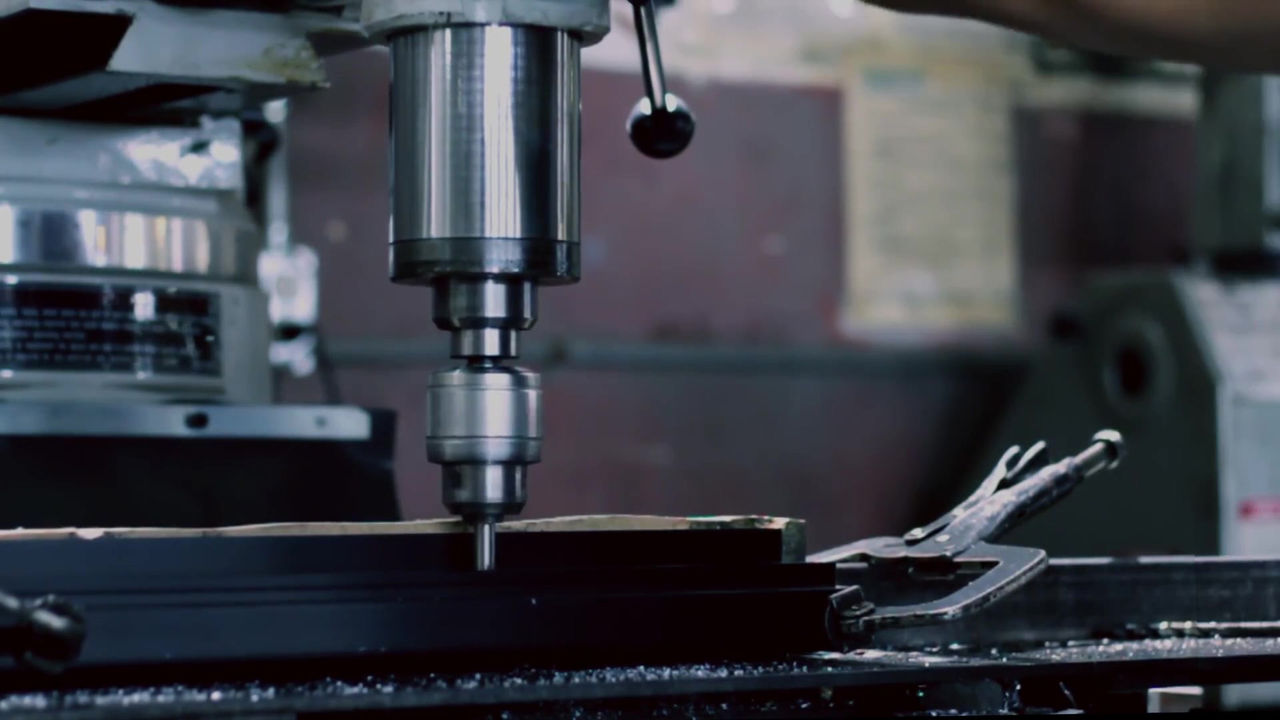

• WIRE FORMING : A roll of gauged wire is bent and shaped into a useful product. We have the capability of forming wires from all gauges, including thin filaments as well as thick wires such as the ones used as springs under automobile chassis. Equipment we use for wire forming are manual and CNC wire formers, coiler, power presses, fourslide, multi-slide. Our processes are drawing, bending, straightening, flattening, stretching, cutting, upsetting, soldering & welding & brazing, assembly, coiling, swaging (or winging), piercing, wire threading, drilling, chamfering, grinding, coating and surface treatments. Our state-of-the-art equipment can be set-up to develop very complex designs of any shape and tight tolerances. We offer various end types like spherical, pointed or chamfered ends for your wires. Most of our wire forming projects have minimal to zero tooling costs. Sample turnaround times are generally days. Changes to design/configuration of wire forms can be made very quickly.

• SPRING FORMING : AGS-TECH manufactures a large variety of springs including:

-Torsion / Double Torsion Spring

-Tension / Compression Spring

-Constant / Variable Spring

-Coil & Helical Spring

-Flat & Leaf Spring

-Balance Spring

-Belleville Washer

-Negator Spring

-Progressive Rate Coil Spring

-Wave Spring

-Volute Spring

-Tapered Springs

-Spring Rings

-Clock Springs

-Clips

We manufacture springs from a variety of materials and can guide you according to your application. Most common materials are stainless steel, chrome silicon, high-carbon steel, oil-tempered low-carbon, chrome vanadium, phosphor bronze, titanium, beryllium copper alloy, high-temperature ceramic.

We use various techniques in the manufacture of springs, including CNC coiling, cold winding, hot winding, hardening, finishing. Other techniques already mentioned above under wire forming are also common in our spring manufacturing operations.

• FINISHING SERVICES for WIRES & SPRINGS : We can finish your products in many ways depending on your choice and needs. Some common processes we offer are: painting, powder coating, plating, vinyl dipping, anodizing, stress relieve, heat treatment, shot peen, tumble, chromate, electroless nickel, passivation, baked enamel, plastic coat, plasma cleaning.